PRODUCTION

Our responsible, goal-oriented and qualified employees realise your wishes and ideas. We ensure the highest standard of quality at an exceptional pace through optimally harmonised work processes.

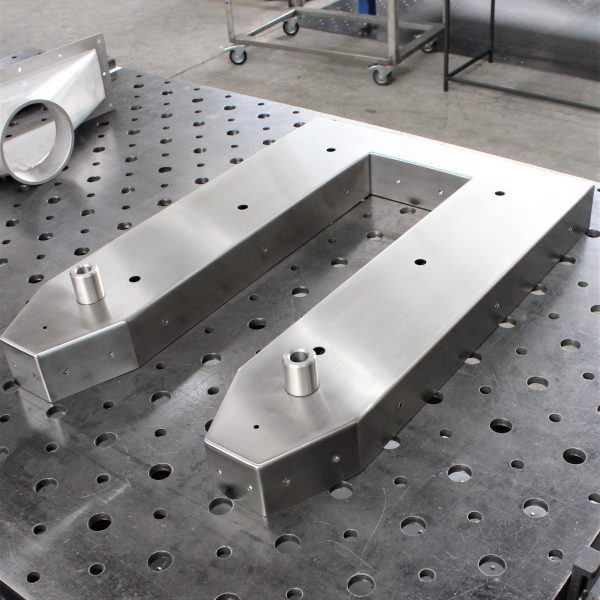

PUNCH-LASER COMBINATION PARTS

TUBE PROCESSING

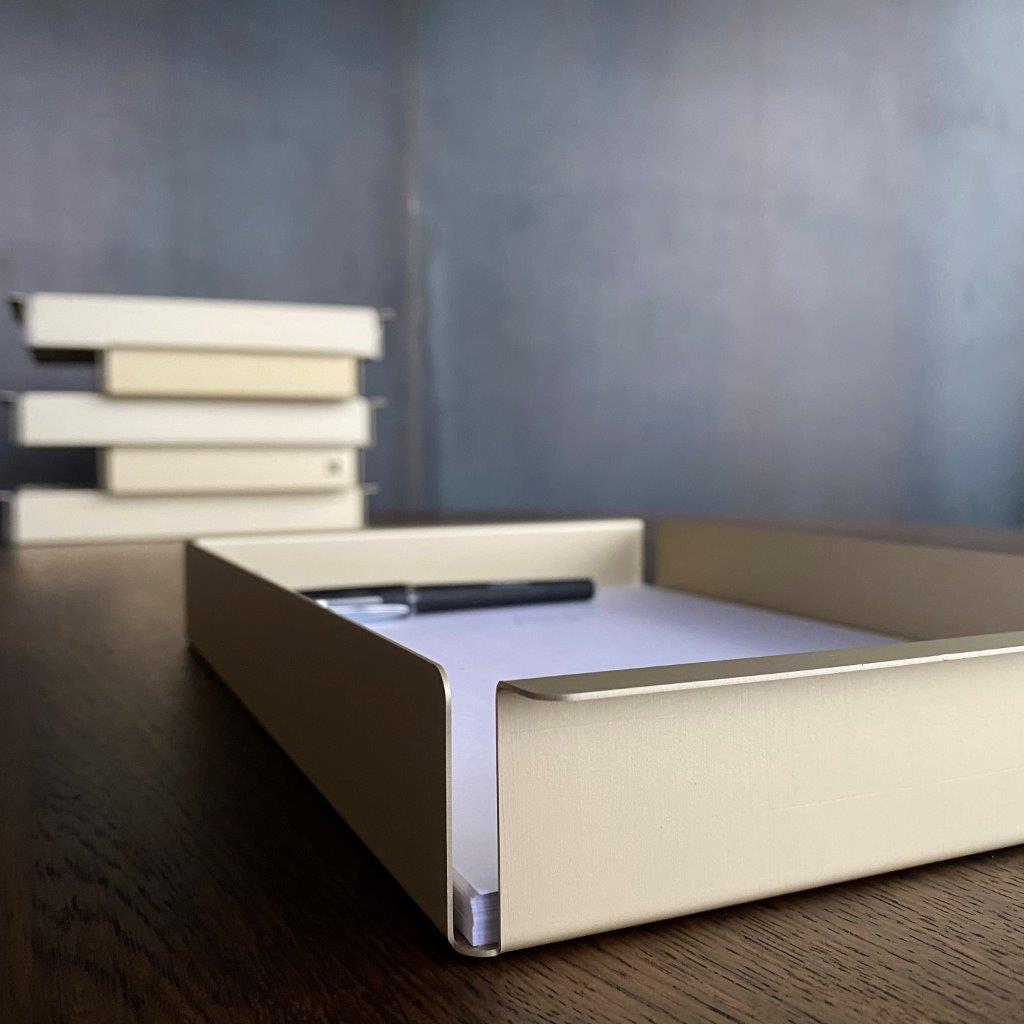

HOUSING CONSTRUCTION

MACHINE PANELLING

DEGRADE

Technical data at a glance

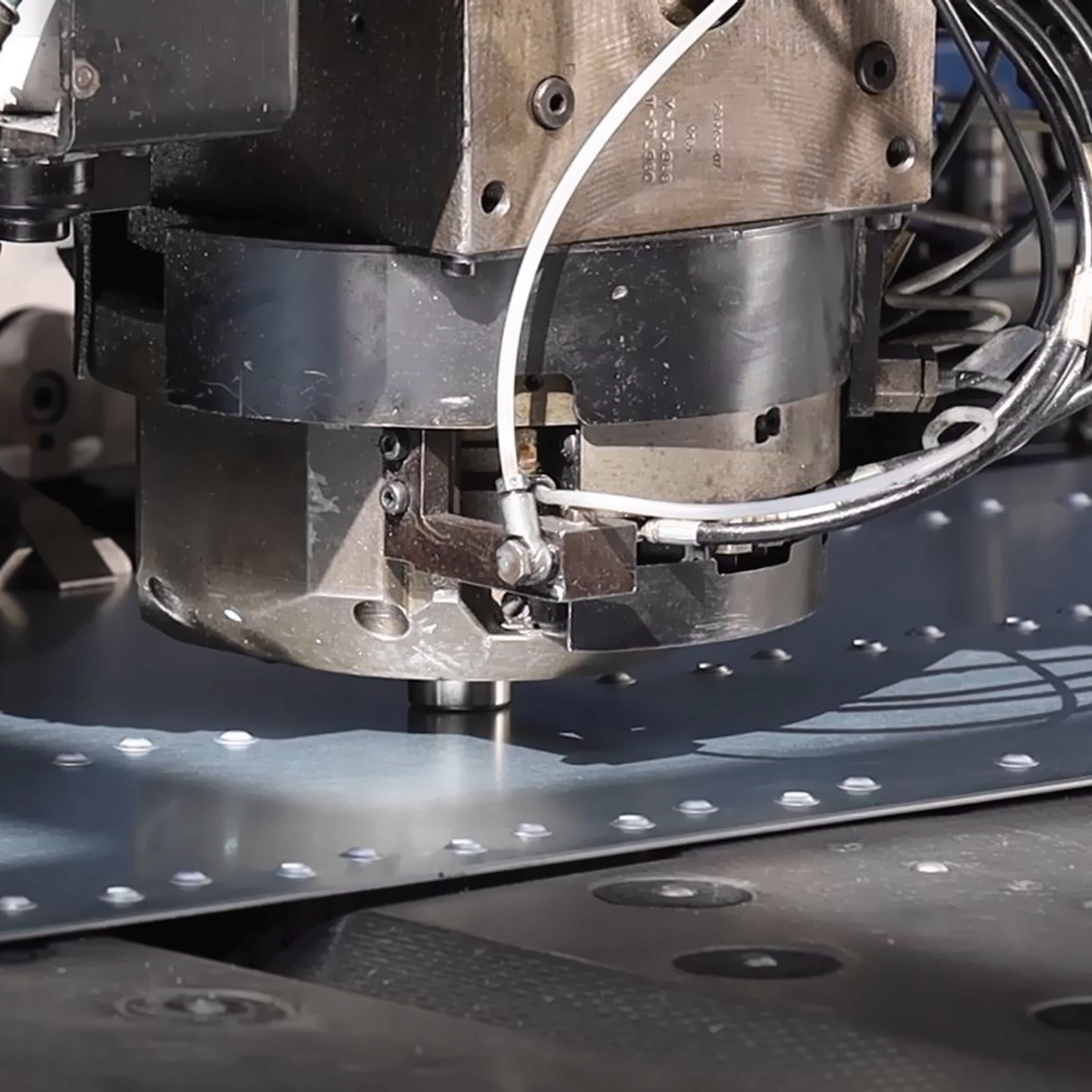

Laser cutting:

Maximum sheet size: 2980 x 1480 mm

Maximum sheet thickness: steel 20 mm / stainless steel 15 mm / aluminium 12 mm / copper 4 mm / brass 4 mm

Machine technology: Fibre

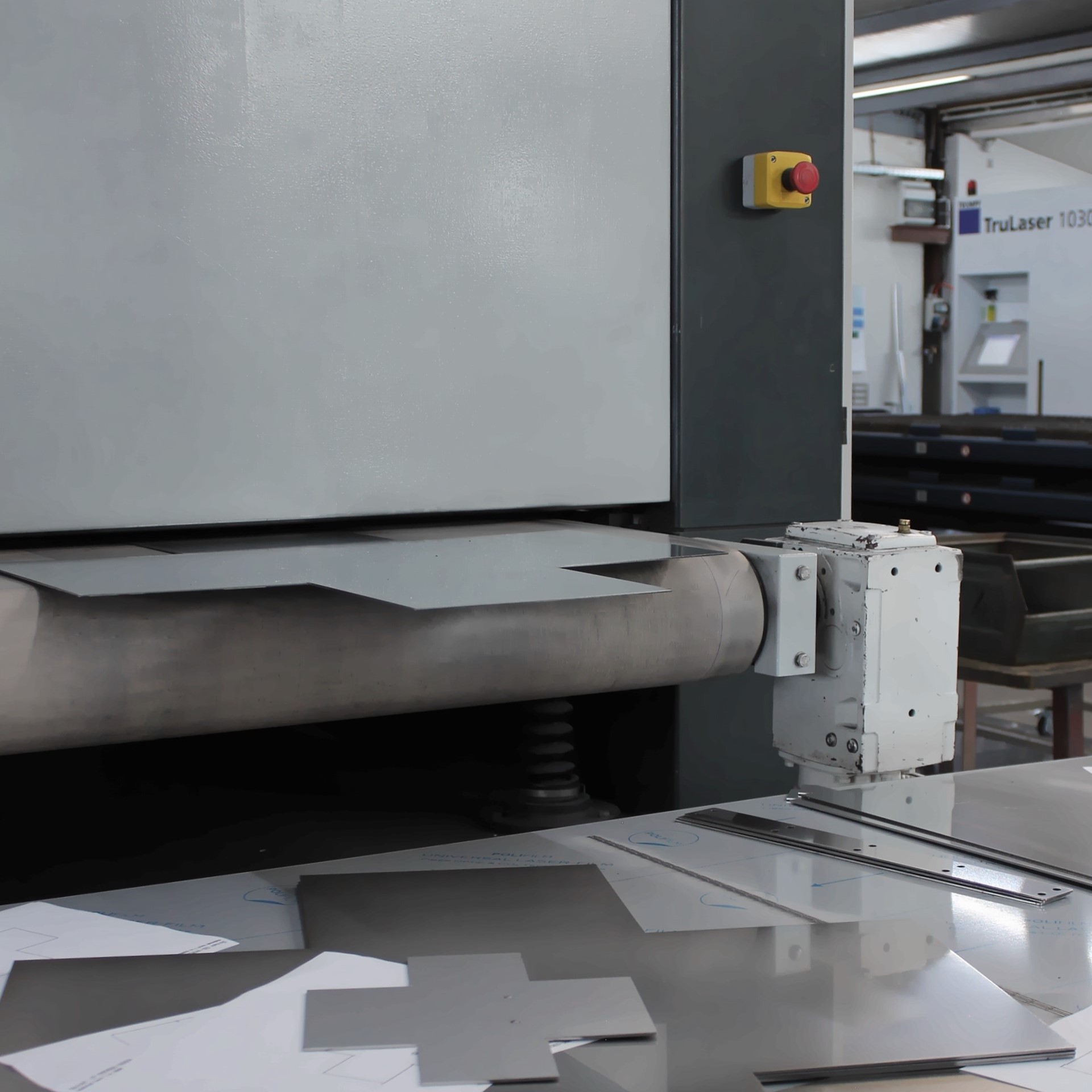

Edges:

Maximum size: 2980 x 1480 mm

Maximum sheet thickness: Steel 6 mm / stainless steel 5 mm

Maximum bending angle: 35 degrees

Tube laser processing:

Minimum leg dimension square tubes: 10×10 mm

Maximum leg dimension square tubes: 60 mm

Minimum wall thickness: steel 1.5 mm / aluminium 2 mm / stainless steel 1 mm

Laser welding – advantages at a glance:

Laser welding eliminates the need for subsequent grinding and straightening

Welding of different material types and thicknesses

Precise energy input

Minimal thermal influence on the material

Welding of complicated seam geometries

High automation capability and welding speed